Condition:

New

Range Of Spindle Speed(r.p.m):

1 - 24000 Rpm

Positioning Accuracy (mm):

0.05 Mm

No. Of Spindles:

Single

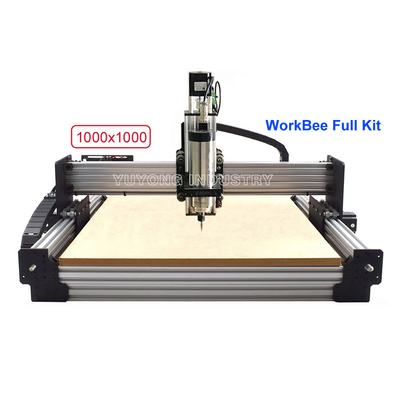

Working Table Size(mm):

1000x1000

Machine Type:

CNC Router

Travel (X Axis)(mm):

800 Mm

Travel (Y Axis)(mm):

770 Mm

Repeatability (X/Y/Z) (mm):

0.05 Mm

Spindle Motor Power(kW):

2.2

CNC Or Not:

CNC

Voltage:

110V/220V

Weight (KG):

54

Control System Brand:

Mach3

Warranty:

1 Year

Key Selling Points:

High-accuracy

Applicable Industries:

Advertising Company, Building Material Shops, Farms, Food & Beverage Factory, Food & Beverage Shops, Food Shop, Garment Shops, Home Use, Hotels, Machinery Repair Shops, Manufacturing Plant, Printing Shops, Restaurant, Retail, Construction Works�

Machinery Test Report:

Not Available

Video Outgoing-inspection:

Not Available

Warranty Of Core Components:

Not Available

Core Components:

Bearing, Engine, Motor

Product Name:

1000x1000 WorkBee CNC Full Kit

Frame Material:

Aluminum

Driving Mode:

Stepper Drive

Motors:

NEMA23 Stepper Motors X,Y & Z.

V-Slot Colour:

Black & Sliver

Power(W):

24V 500W Output

After-sales Service Provided:

Online Support

Local Service Location:

None

After Warranty Service:

Online Support

Showroom Location:

None

Marketing Type:

New Product 2020

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!